LED UV Printing Services In Atlanta, GA

Experience the future of printing with Tucker Castleberry's state-of-the-art LED UV Printing Services. Our team in Atlanta, GA, has embraced the latest technology, installing LED-UV systems that revolutionize our printing capabilities and deliver exceptional quality.

What is LED UV Printing?

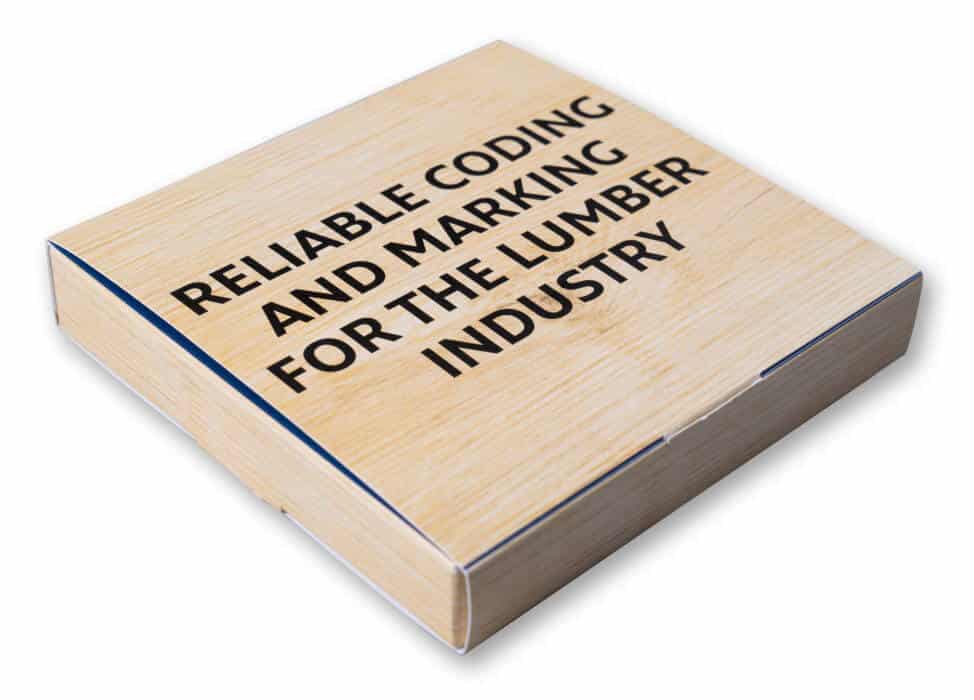

LED UV printing is a groundbreaking technology that transforms the traditional printing process. With our recent investment in LED-UV curing technology from AMS Spectral UV, our UV print shop can now print on various substrates, including vinyl, plastics, and styrene. Unlike conventional printing, LED-UV technology dries the press sheet before reaching the delivery stage in the press, ensuring sharper dots, minimal dot gain, and no marking. The vibrancy of the colors is increased, producing a sharper image that features fine line detail.

The Benefits of LED UV Printing

Our LED UV printing services offer numerous advantages. Instant ink curing translates into no powder or drying time required. With this technology, our UV printing company can work with substrate material options that don't absorb inks, making it ideal for heat sensitivity. LED-UV lamps operate significantly longer than traditional UV lamps, reducing maintenance costs. Additionally, our LED-UV inks are free of volatile organic compounds (VOCs), contributing to a safer and more eco-friendly printing environment. Say goodbye to heat, mercury, and ozone in the press room.

Our LED UV Printing Services and Systems

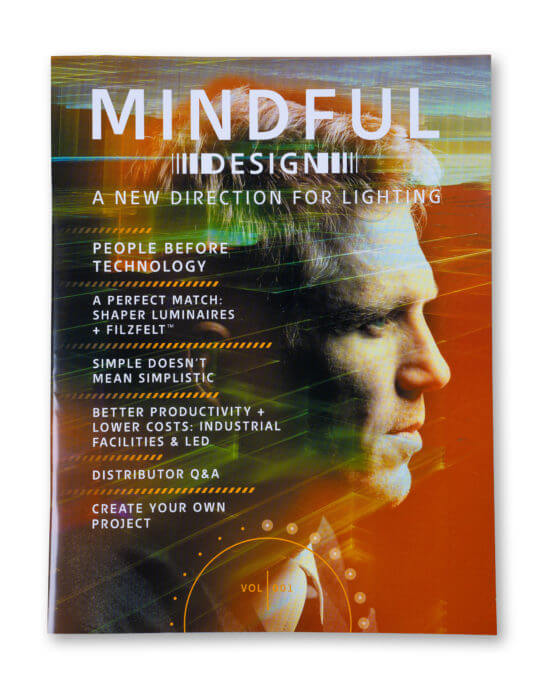

The revolutionary LED-UV technology incorporated into our ManRoland 700 presses and Komori GL840PC enables instant curing, eliminating the need for drying time and powder. It opens up creative possibilities with the ability to create different effects, patterns, and textures using reticulation. Our Reticulating Varnish creates textured and raised coatings, giving depth and dimensionality to words and images.

AMS Spectral UV's LED-UV systems, considered top-of-the-line in the market, have revolutionized our UV direct and UV offset printing capabilities. Utilizing this printing UV technology, we ensure optimal curing intensities and flexibility for various printing needs. Our commitment to customization means each LED-UV system is tailored to fit the specific press, providing efficiency, precision, and fast turnaround times on your printing orders.

Get LED UV Printing Services in Atlanta, GA

Are you ready to experience the future of printing? Give us a call today at 478-210-2436 to learn more about the possibilities of our LED UV direct printing and offset printing services. Enhance your print projects with more vibrant colors, sharper images, and safer printing technology. We are ready to help bring your vision to life!

Frequently Asked Questions

What is offset printing?

Offset printing is a method that uses plates to transfer an image onto a rubber applicator. The applicator is then rolled onto the finished product.

What is the offset printing process?

This method of printing involves creating an inked image on a printing plate, which is often aluminum. The printing plate is then placed on a rubber cylinder, allowing for the image to be transferred onto paper or another material.

What is offset printing used for?

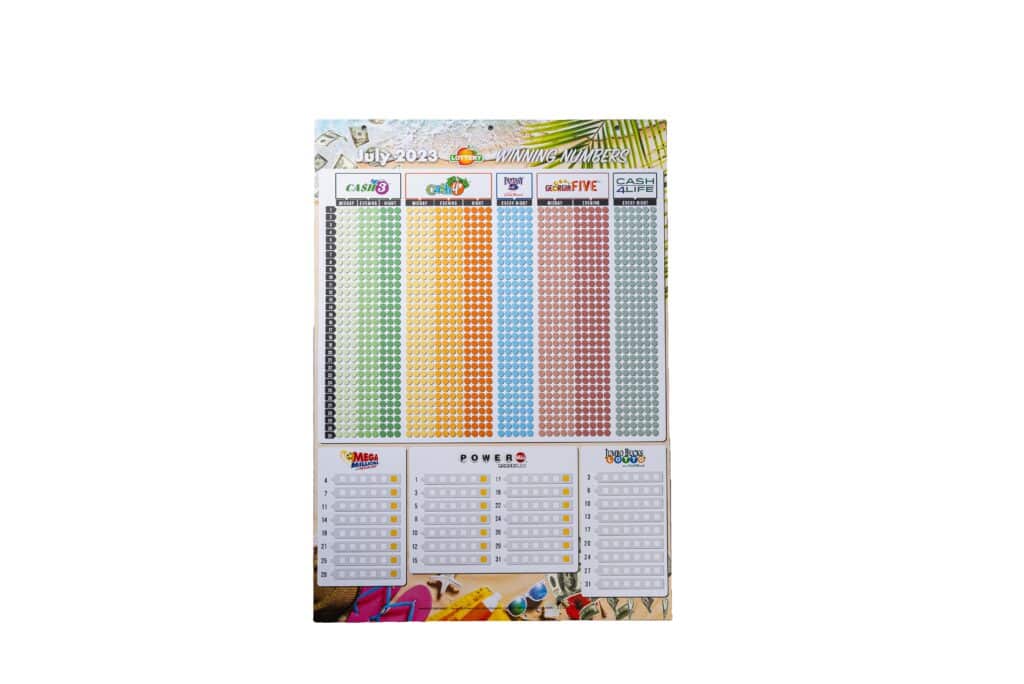

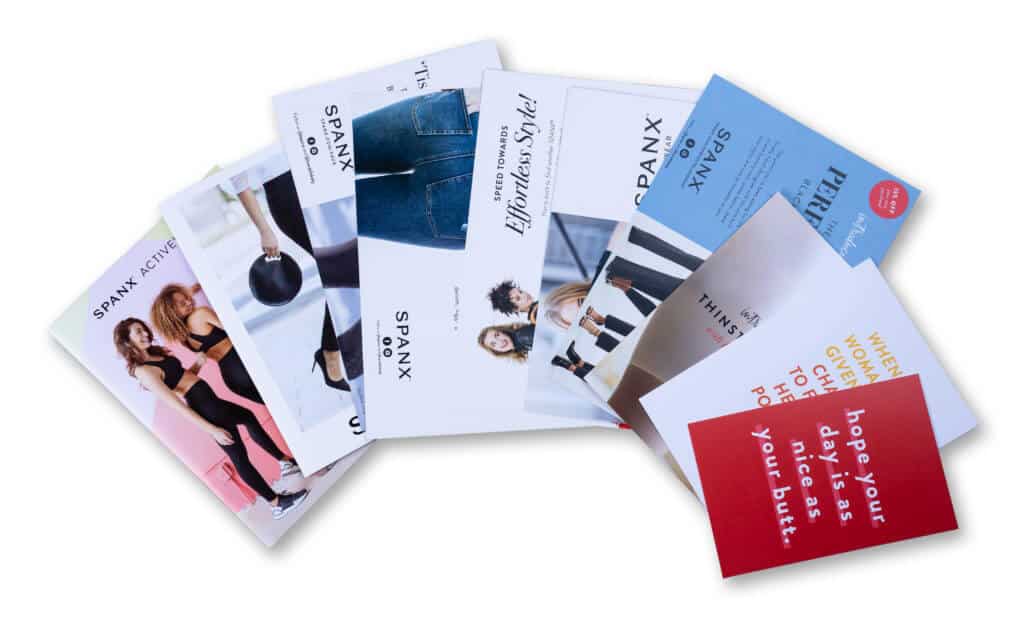

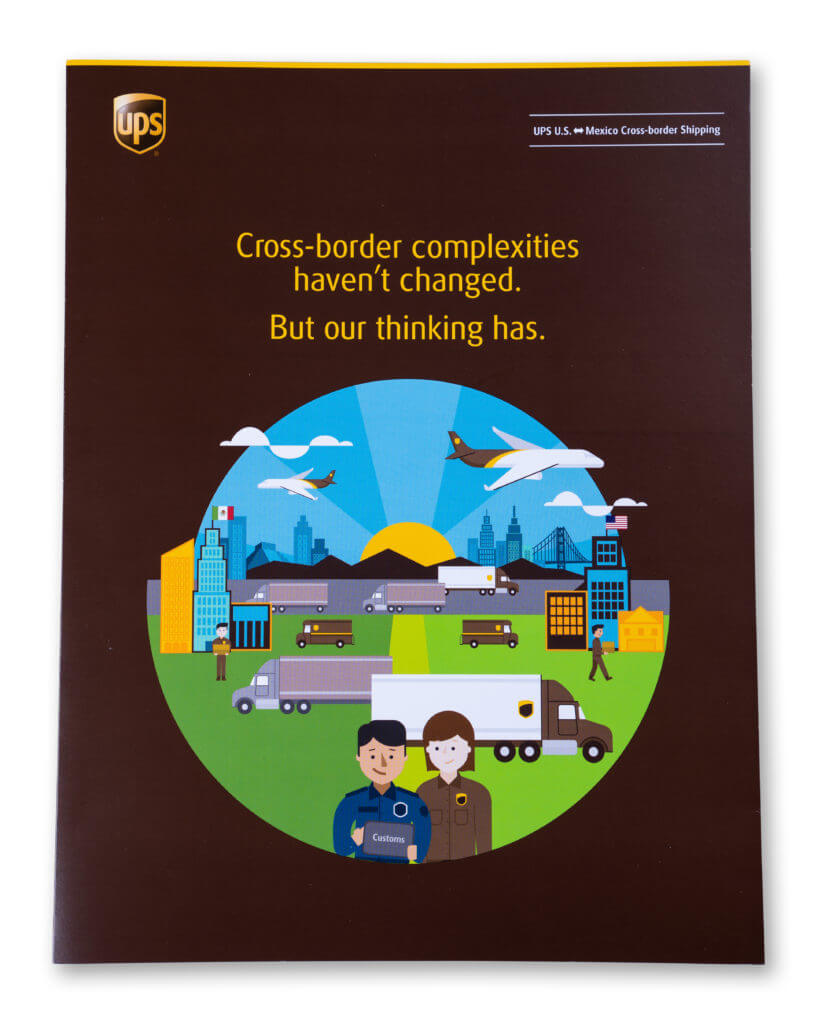

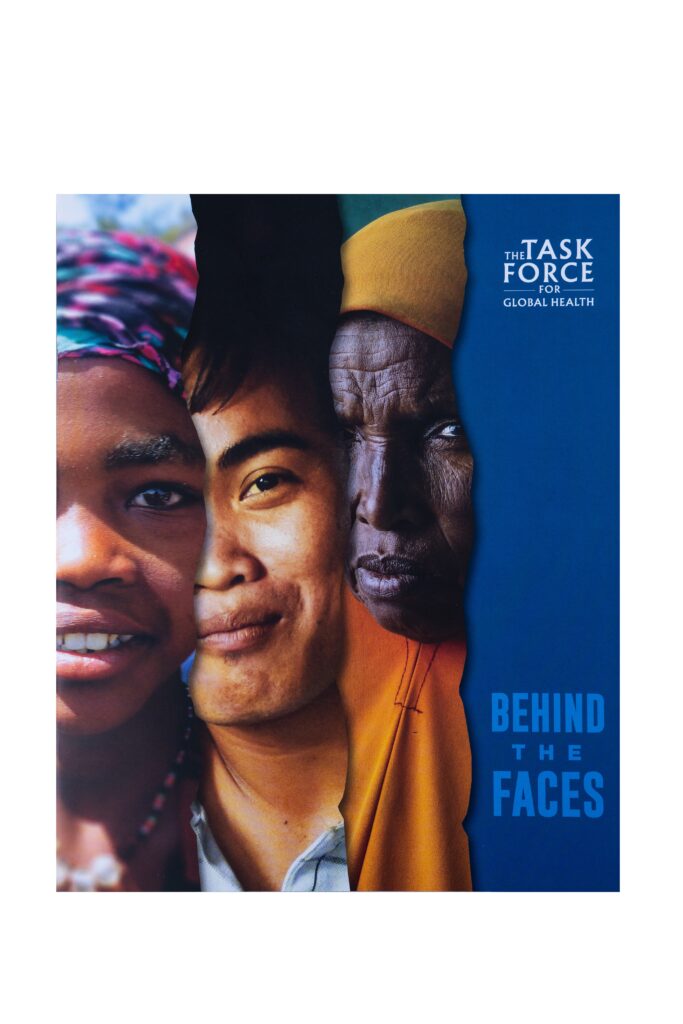

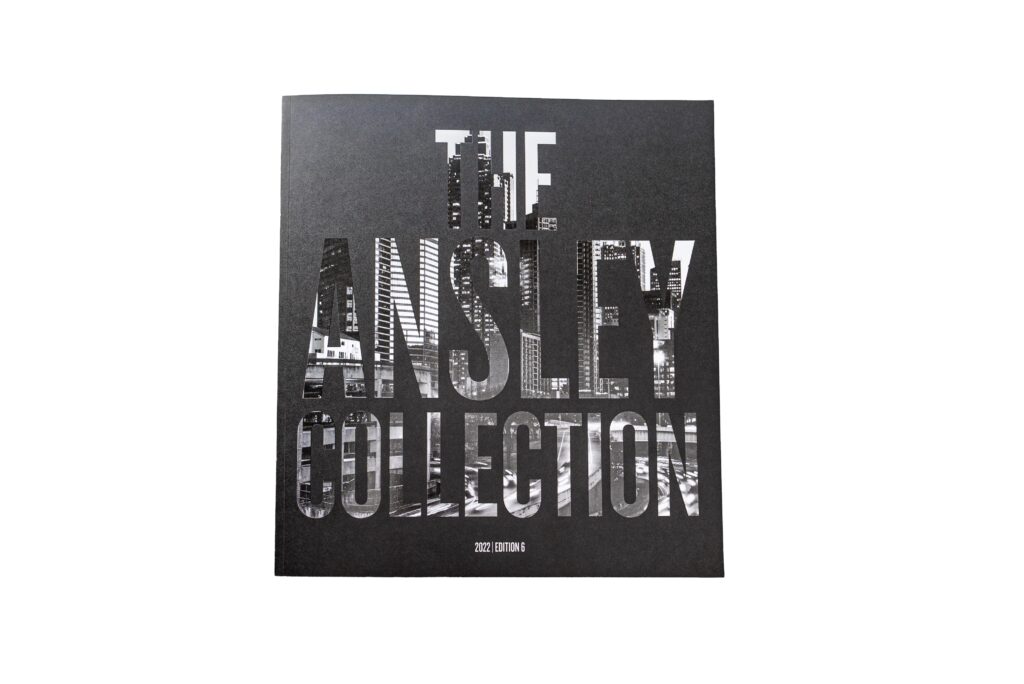

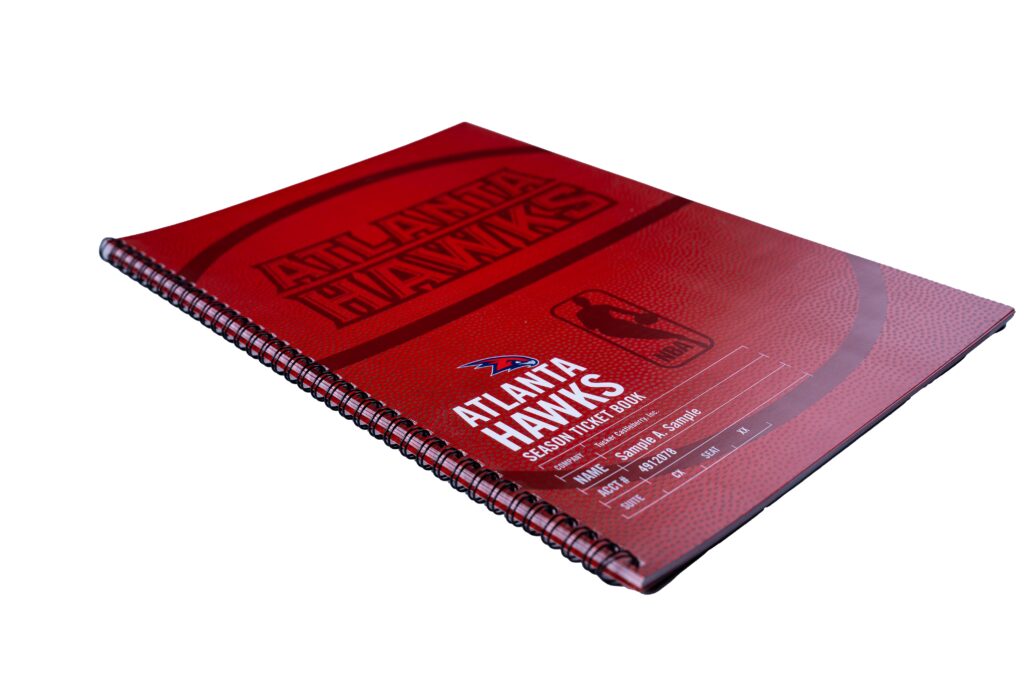

Offset printing is a commonly used method in a variety of commercial printing projects, especially with most types of high quality printed materials. Offset printing can be used with magazines, stationery, books, brochures, newspapers, and more.

What is offset lithographic printing?

Offset lithographic printing is another term for offset printing. An image is put on a thin metal plate and then moved or transferred to a rubber blanket to then be placed onto a material such as plastic or paper.

How many types of offset printing are there?

There are two main types. One is a wet offset which uses water and moisture. The second is a waterless offset.

What's the difference between offset and digital printing?

These are two significantly different forms and they are used in different ways. Digital printing does not use plates in the same way that offset printing does. Instead, digital printing uses toners or liquid ink to create the images on the final product. Offset printing allows for the ink to be placed in water or a solution that is then transferred to a rubber blanket and finally onto the finished product.

Gallery

Get Informed

Sign up for our email!